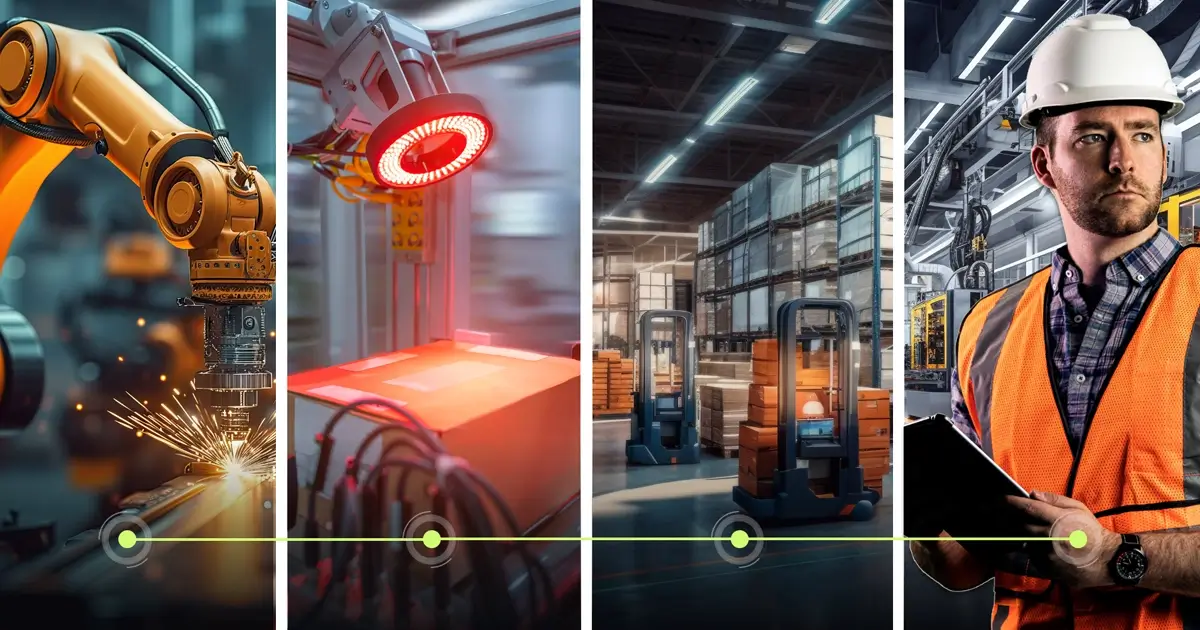

Hyundai’s $7.6B EV Metaplant

Hyundai has unveiled a $7.6 billion state-of-the-art electric vehicle (EV) Metaplant in Georgia, USA. The facility boasts 300 Autonomous Guided Vehicles (AGVs) and 475 robotic arms, aiming to produce 500,000 EVs and hybrids annually. The plant operates on renewable energy and hydrogen-fueled logistics, reflecting Hyundai’s commitment to green production. However, concerns over reduced human labor persist, as the plant currently supports over 1,300 jobs, with plans to expand to 8,500 on-site positions and 7,000 more through supplier.

Amazon’s AI-Driven Logistics Enhancement

Amazon is integrating artificial intelligence to enhance its delivery and logistics operations. The company is developing agentic AI-driven warehouse robots capable of performing multiple functions such as unloading trailers and retrieving parts on command. Additionally, Amazon is leveraging generative AI to create advanced mapping tools for its delivery drivers, aiding in navigation through complex locations. These advancements aim to boost efficiency, particularly during high-demand seasons, and reduce emissions and waste.

AI in Quality Control and Predictive Maintenance

AI-Driven Quality Control in Ludhiana

A recent workshop organized by the Chamber of Industrial & Commercial Undertakings (CICU) in Ludhiana emphasized the transformative impact of artificial intelligence on modern manufacturing. The event highlighted how AI is enhancing operational efficiency through automation, predictive maintenance, and cost reduction. Experts discussed applications of machine learning in production, real-time data analysis, and AI-driven quality control systems. The role of generative AI, including natural language processing and foundation models, was also explored. Demonstrations showcased the integration of AWS cloud-based tools into industrial operations to boost performance across sectors.

AI for Sustainability and Ethical Manufacturing

AI-Driven Sustainability Initiatives

Companies are increasingly adopting AI to promote sustainable manufacturing practices. Platforms like ABB’s Ability™ and Schneider Electric’s EcoStruxure™ leverage AI and data analytics to enhance energy efficiency, reduce waste, and improve resource utilization. These solutions provide real-time insights and control over processes, empowering factories to make data-driven decisions that contribute to more sustainable and eco-friendly manufacturing practices.

Emerging AI Technologies in Manufacturing

Factory in a Box Concept

The “Factory in a Box” concept involves using portable, modular, self-contained factories that can be easily transported to different locations as needed. These factories utilize AI systems along with IoT to autonomously manage production tasks, optimizing workflows and reducing human intervention. Machine learning algorithms analyze data from sensors and equipment to improve efficiency and adapt processes in real-time. This approach allows companies to bring production closer to their consumers, reducing shipping costs and turnaround times.

These advancements underscore the growing role of artificial intelligence in transforming manufacturing processes, enhancing efficiency, quality, and sustainability